No Leakage Vertical Multisatge Pump for Buliding

Basic Info

Model No.: DL

Product Description

Model NO.: DL

Max.Capacity: 50-100 L/min

Material: Cast Iron

Assembly: Liquid Pumps

Start Up: Electric Pump

Application: Industry, Building

Media: Water

Theory: Centrifugal Pump

OEM: Ok

Trademark: Tongke

HS Code: 8413709990

Max.Head: >150m

Driving Type: Motor

Structure: Multistage Pump

Power: Electric

Type: Centrifugal Pump

Industry: Industry

Performance: No Leakage Pump

Standard: Yes

Head: up to 120m

Origin: China

DL series No leakage Vertical Multistage Centrifugal Pump for buliding

Vertical, single suction, multistage, sectional and centrifugal ones and used for transporting pure water and the liquids below 85 C and with the physical and chemical natures similar to water's.

Our Advantage have to say!

Compact structure √

High efficiency √

Low noise √

Well use for Water supply, Buliding water supply, Fire-fighting ,Centralized heat supply system.

Running Data

| Diameter | DN 40-200mm |

| Capacity | 6-300 m3/h |

| Head | 24-280 m |

| Liquid Temperature | up to 85 ºC |

| Operation pressure | ≤ 30bar |

√ Tongke Technical Design Description

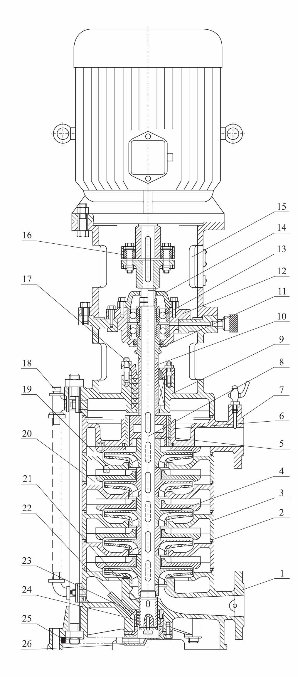

Δ DL series Vertical Multistage Centrifugal Pump Hydraulic Pump is vertically structured, its suction port is located on the inlet section(lower part of pump), spitting port on the output section(upper part of pump), both are horizontally positioned. The number of stages can be increased or decreased per the required head at use. There are four included angles of 0 ,90 ,180 and 270 available for selecting per different installations and uses in order to adjust the mounting position of the spitting port (the one when ex-works is 180 if no special note is given).

Δ Major parts of the pump: inlet, middle and outlet sections, impeller, guide vane, guide vane on outlet bearing, shaft sleeve, balance drum and sleeve, link stand etc.

1. The inlet, middle and outlet sections, guide vane, guide vane on outlet section are all made of cast iron and mutually form the working room of the pump.

2. The impeller is made of cast-iron, Liquids go in from one side along with the shaft and an axial force may exist because unequal pressures on both front and back of the impeller.

Most of the force is made balanced by the balance drum while its residual is supported by the ball bearing on the upper end of the shaft.

3 The shaft is made of qualified carbon steel and in its middle the impeller, balance drum and shaft sleeve are mounted, which are fixed with pins and shaft sleeve nuts on the shaft to form the rotor. On one end of the shaft a lower shaft sleeve is mounted, which is fitted with the plastic bearing, and on the other the ball bearing is mounted to support the rotor and on the top of it a clutch is mounted and directly connected to the motor.

4. Both balance drum and sleeve form the balance device of the pump and can be replaced when worn out.

5. The shaft seal can not only use soft filling but also be changed with mechanical seal, when using soft filling, the shaft sleeve can be replaced when worn out and, when as the mechanical seal, the pressure water inside of the balance room is used for lubrication and cooling. When as the filling seal, the 3/8'' flexible union on the

outlet section is used through the flexible pipe to drain the water leaked from the filling body to the underground ditch to keep the place around the pump clean.

6. The bearing on the upper end of the pump uses molybdenum disulfide grease for lubrication.

√ Structural Diagram for DL series Vertical Multistage Centrifugal Pump for buliding

|

Attention: More detailed technical data for this pump please contact Tongke. Main parts for Multistage Centrifugal Pump Hydraulic pump

Attention: Particular material for project please contact Tongke engineer for suggestions. Company Image for Tongke  Production Process  International Certificate  Service Twenty years design and engineering experience and More than ten years over sea market Experience. Tongke provide most professional and thoughtful Pre-sales and After service. Technical training Equipment evaluation Installation and debugging Troubleshoot Maintenance Update and improvement Commitment to the service 1.One-year warranty. Provide technical support free all-life of the products. 2.Keep all-life contacting with clients, get feedback on use of the equipment and make the products quality continually perfected. 3.Hot-line of service is available in 24h, responded in 8h. Your call and mail is welcome at any time

Contact us if you need more details on Pump for Buliding. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Vertical Multisatge Pump、Pump. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Industry Pump Other Products

Hot Products New Design Channel Type Single Drum Wastewater GrindersDiesel or Electric Self Priming Sewage Centrifugal PumpCentrifugal PumpWater Treatment Trash/ Sewage Dewatering Self-Priming PumpDiesel Engine Self Priming Centrifugal Trailer Mounted Water PumpAxial Flow and Mixed Flow Submersible Sewage Pump for IrrigationDiesel Engine Rotor Water Pump (set)Engine Water Pump Set for Industry Water SupplyUL Listed Double Suction Split Casing Fire-Fighting PumpStainless Steel Chemical Electric Centrifugal Pump for OilSmall Type Sewage Submersible Water Pump with MotorAxial Flow and Mixed Flow Submersible PumpHigh Efficency End Suction Circulating Water Pump for Hot WaterVertical Turbine Pump for Salt WaterMovable Diesel Engine Dry Self Priming Water PumpHigh Efficency Dry Priming Self Priming Water Pump | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||