Multistage High Pressure Chemical Oil Pump (API 610 BB4)

Basic Info

Model No.: MC

Product Description

Model NO.: MC

Type: Oil Pump

Performance: Corrosion

Standard: Yes

Head: up to 120m

Origin: China

Flow Rate: up to 600m3/H

Drive: Electric

Application: Chemical Pump, Oil Pump

OEM: Ok

Trademark: Tongke

HS Code: 8413709990

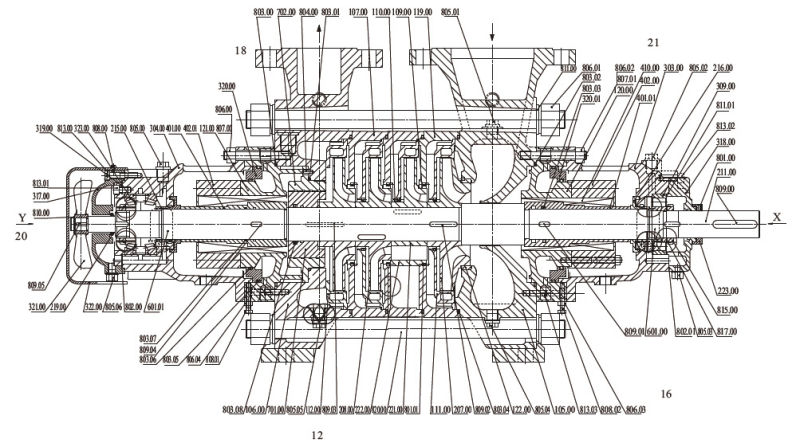

MC Series API 610 BB4 High pressure Multistage Chemical Pump for oil

Δ MC series are horizonta lmultistage Centrifugal Pumps.

Δ Balance drum, disc type, balancing axial thrust

Δ Radial bearing and angular-contact bearing gather together to bear the rest force

Δ Cartridge mechanical seal design

Δ Standard API610 Flush and cooling.

Δ According to different temperature of the liquid to select right structure, feet support and central bearing.

Δ Smart arrangement of suction and discharge can meet different demands.

Δ Design different hydraulic models to expand BEP area to ensure pump work in high efficiency at different work condition.

Δ Suction type first stage impeller improves anticavitation performance.

Δ Easy and convenient maintenance design comforts clients.

Δ CW viewed from drive end.

Running Data

| Diameter | DN 40-200mm |

| Capacity | Up to 600 m3/h |

| Head | Up to 1200m |

| Liquid Temperature | -80~ +180ºC |

| Working pressure | ~ 15MPa |

√ Where can use our MC Series API 610 BB4 High pressure Multistage Chemical Pump ?

For transferring clean liquid or little corrosive liquid.

Δ Industrial water supply equipments

Δ Thermal power plant

Δ Refinery plant

Δ Petrochemical industry

Δ Cooling or heating system

Δ City water supply devices

√ MC Series API 610 BB4 High pressure Multistage Chemical Pump Advantage have to say!!

SEALS √

Cartridge type mec.seal for drive end and Non-drive end

Cartridge mec.seal can be equipped With single or tandem double mechanical seal

For some work condition, it can also be equipped with packing seal system.

For equipping sharp quenching at back of the mech anical seal, sharp quenching packing system should be fit to reduce leakage of sharp quenching fluid.

Housing cooling system can be supplied for various kinds of seal parts

HYDRAULIC PART √

Suction type first stage impeller improves anti-cavitation performance

Position of impeller has axial gap, changes of temperature can reduce deformation of shaft.

Different hydraulic models equipment improves HEP design and ensures high efficiency for the whole series.

As per requirements, inducer can be equipped to improve anti-cavitation performance.

SUCTION SECTION AND DISCHARGE SECTION √

Direction of outlet and inlet can be optional.

Different supporting can be selected according to different temperature.

Standards of flanges can be decided by users themselves.

BALANCE DEVICES √

Balancing axial force with balance drum or disc, rest force by thrust bearings.

More detailed technical data and operating condition will be referred to related technical information of our company or contact our enginner.

API 682 Classic seal flush plan

| PLAN 11 | PLAN 21 | |

| Working fluid enters seal housing through pipe line from pipe discharge | Circulating liquid enters sealing housing cooled by heatexchanger at discharge of pump | |

| The plan mainly for condensated water, normal temperature steam, diesel etc (Not for high temperature condition. | Circulating fluid enters seal housing after cooled by heater exchanger from pump discharge. | |

| PLAN 32 | PLAN 54 | |

| Flush from outside | Back to back double mechanical seal for outside flush resource | |

| Flush fluid enters seal housing from outside, the plan mainly for liquid with solid or impurities.(Attention outside flush fluid affect the liquid pumped) | ||

| PLAN 11+52 | PLAN 53 | |

| Classic flush plan for tandem double mechanical seal, front seal plan 11, back non-pressure flush, back seal with effect ring. | Circulating pressured liquid flush BACK TO BACK double mechanical seal, can also be for tandem double mechanical seal back seal flush plan. | |

Attention: Above are only part of normal seal plans, according to specific work condition, we can supply the best seal plan.

Company Image for Tongke

Production Process

International Certificate

Service

Twenty years design and engineering experience and More than ten years over sea market Experience. Tongke provide most professional and thoughtful Pre-sales and After service.

Technical training Equipment evaluation

Installation and debugging Troubleshoot

Maintenance Update and improvement

Commitment to the service

1.One-year warranty. Provide technical support free all-life of the products.

2.Keep all-life contacting with clients, get feedback on use of the equipment and make the products quality continually perfected.

3.Hot-line of service is available in 24h, responded in 8h.

Your call and mail is welcome at any time

For our API 610 BB4 high pressure Chemical Process Pump

| Contact | Mr Seth Chen |

| Telphone | 0086-13817768896 |

Contact us if you need more details on High Pressure Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Chemical Pump、Oil Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : API Chemical Pump

Premium Related Products

Other Products

Hot Products

New Design Channel Type Single Drum Wastewater GrindersDiesel or Electric Self Priming Sewage Centrifugal PumpCentrifugal PumpWater Treatment Trash/ Sewage Dewatering Self-Priming PumpDiesel Engine Self Priming Centrifugal Trailer Mounted Water PumpAxial Flow and Mixed Flow Submersible Sewage Pump for IrrigationDiesel Engine Rotor Water Pump (set)Engine Water Pump Set for Industry Water SupplyUL Listed Double Suction Split Casing Fire-Fighting PumpStainless Steel Chemical Electric Centrifugal Pump for OilSmall Type Sewage Submersible Water Pump with MotorAxial Flow and Mixed Flow Submersible PumpHigh Efficency End Suction Circulating Water Pump for Hot WaterVertical Turbine Pump for Salt WaterMovable Diesel Engine Dry Self Priming Water PumpHigh Efficency Dry Priming Self Priming Water Pump